Seed Treatments

Services for BioControl Manufacturers

AgraForm specializes in seed treatments designed to “dress” seeds to client specifications. If you need to scale-up manufacturing of your biocontrol product, AgraForm has the equipment and facility to help you do that.

Our onsite formulation lab guarantees quality and our convenient location with truck access makes distributing your products easy. Our biocontrol spray dryer can produce upwards of 30 thousand pounds-per-day and is one of the many onsite services we offer biocontrol manufacturers. The full list of services we offer for biocontrol products includes:

- Lab Formulation

- BioControl Bulk Formulation

- Milling Services

- Biocontrol Spray Drying

- Packaging - Rail, Tankers, Totes, Drums and Jugs

- Tank Farm Services

Request a Quote

“*” indicates required fields

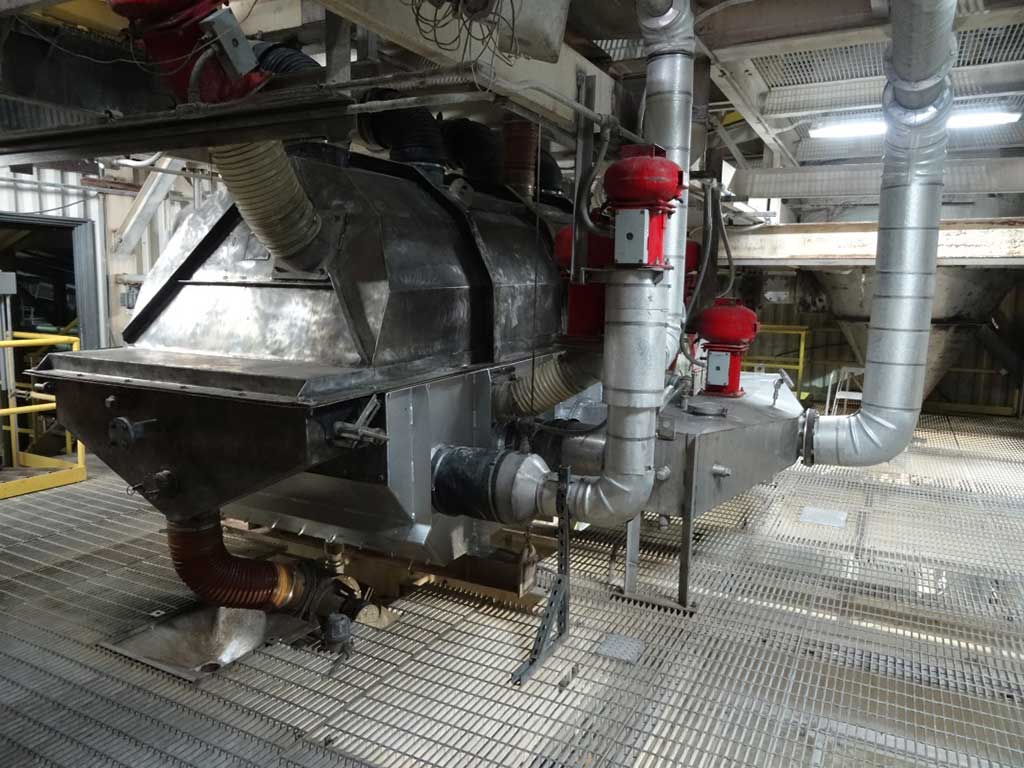

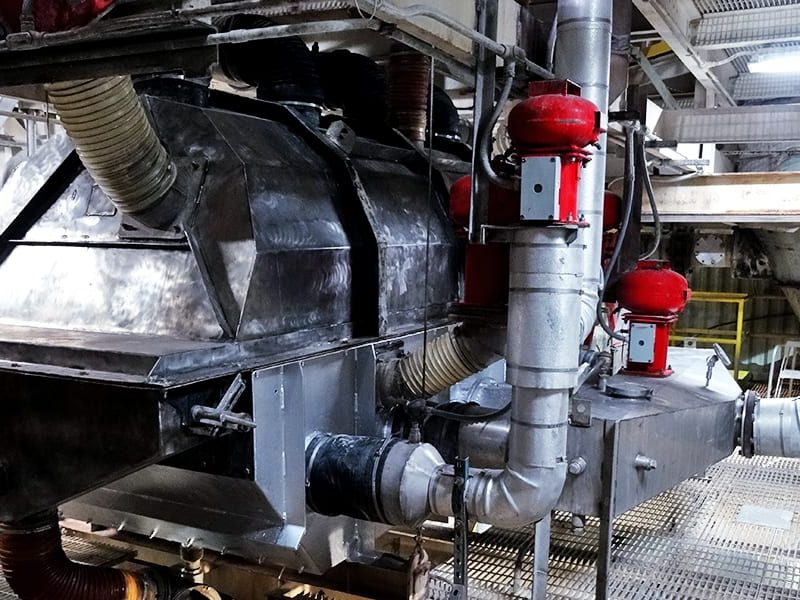

Our Biocontrol Spray Dryer

BioControl Products FAQ's

What are biocontrol products?

Biocontrol products, or biocides, are chemicals used to reduce or eliminate biological elements such as bacteria, microbes and pathogens in various products and applications. Biocontrol products may contain biological elements themselves, such as bacteria that ingest certain metals. Specific types of biocontrol products include:

- Preservatives that protect products from microbial contaminates that can spoil, decrease the life-span or compromise product quality. Common products with preservative biocides include: paints, coatings, fabrics, latex, fuel and metalworking fluids

- Water treatment chemicals that reduce fouling, maintain energy efficiency and protect equipment

- Marine antifoulants that protect ship hulls, docks and other water-submerged structures from buildup of barnacles, slime and macroalgea that cause degradation over time

- Wood preservatives that extend the useful life of wooden products

- Public health biocontrol products such as water and food treatments, and cleaning products that eliminate pathogens in hospitals, homes and businesses

For additional information, please visit: https://biocides.americanchemistry.com/About.html

How do you maintain quality for biocontrol manufacturers?

Our process formulation and scale-up experts sample and test your product at the appropriate stages to ensure products are manufactured to industry and client standards. AgraForm’s in-house formulation lab provides a variety of testing equipment including:

- Malvern particle size analysis

- Digital moisture balance

- Gas chromatography (GC)

- High pressure liquid chromatography (HPLC)

- Ion exchange chromatography (IC)

- Karl Fischer titration moisture analysis

- Performance property testing

- Pilot scale mill

- Titrations and wet chemistry

- Viscosity testing (Brookfield and Kinexus Dynamic Viscosity)

For additional questions about biocide quality assurance and testing, please contact us.

What do biocontrol spray dryer & contract manufacturing services cost?

Cost is mainly determined by several factors:

- What raw materials are required to manufacture your product? Raw material costs can vary, but we have many common process formula inputs onsite in bulk that offer you a cost advantage at AgraForm.

- What processing steps are involved? Some products require more complicated mixing, drying and processing steps, which adds costs.

- How much product are you planning to contract out? As a bulk biocontrol manufacturer, we can offer discounts to larger batches of product outputs, but also offer an affordable test facility for smaller product runs.

- Which tests must be performed to ensure quality standards are being met? More tests, and certain types of tests, increase expense but are necessary to ensure quality. Our experienced process experts make sure your products are up to spec without costing you more by over-testing.

There are other varying factors, but those are the largest ones. For an exact cost estimate, please contact us.

How do I get started with biocontrol contract manufacturing?

If you have a lab formulation and want to start scaling up to full manufacturing, now is the time to reach out to AgraForm. Simply Call (314) 353-5325 or fill out our contact formand one of our process experts will get in touch with you by the next business day.

We offer biocide manufacturers turnkey bulk formulation and scale-up services including product formulation, mixing, spray drying, packaging and shipment.