Bulk Formulation

We offer bulk formulation and liquid formulation services to agriculture and chemical companies. You develop, design and distribute products. We manufacture them — safely, efficiently and to the highest quality standards.

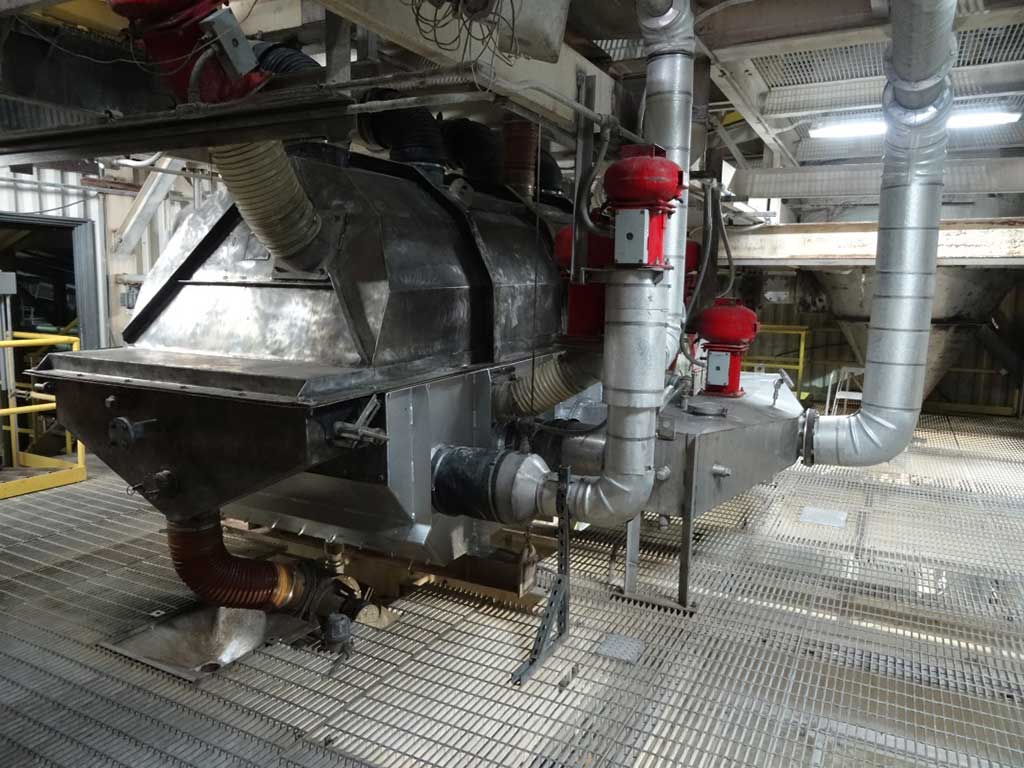

Our 20,000+ sq. ft. bulk formulation facility includes mass blending and milling production capabilities. We’re set up specifically to help companies like yours scale production.

We provide five (5) separate trains for blending and milling production flexibility. In addition, we provide all the equipment needed to deliver bulk formulation and liquid formulation on-demand:

- 8 Charging/Mill tanks with ~5k gallon batch capabilities

- 1500-3000 gallon batches can be run for Qualification or EO runs

- Siefer Mills (pre-grinder)

- 200 liter Dyno Mills

- 280 liter Dyno Mills

Control Room and Process Control Technology

Our manufacturing process is tightly measured, monitored and controlled every step of the way. From our state-of-the-art control room, we leverage the latest manufacturing technologies to drive performance. Our Op-Stations track and log process variables for real-time and historical data analysis. Multiple stations allow simultaneous monitoring and dynamic access to the formulation process.

Our integrated Controls & Admin Local Area Networks (LANs) provide constant insights with:

- Process data — live and historical

- Batch calculation tools

- Safety data (MSDS, CSMS, OSHA, DOT, etc.)

- Environmental data

- Quality control data

- And more

No matter what is happening on the plant floor, we know about it, and you do too — our processes are tight, so your products are manufactured to the highest standards.

Request a Quote

“*” indicates required fields

Blending & Controls Room

Bulk Formulation FAQ's

What are Bulk Formulation Services?

Bulk formulation services are a suite of chemical formulation services provided by manufacturing facilities to chemical producers to blend and produce chemicals in bulk. Formulation entails the process of manufacturing chemical products through an expert, third-party manufacturing facility.

What is Liquid Formulation?

Liquid formulation is the process of combining, often via blending, liquid chemical substances to create a final chemical product. Liquid formulation is often provided by third party manufacturing specialists that manage the process with specialty liquid formulation facilities, equipment, technologies and personnel.

How Do I Get Started?

Liquid formulation is the process of combining, often via blending, liquid chemical substances to create a final chemical product. Liquid formulation is often provided by third party manufacturing specialists that manage the process with specialty liquid formulation facilities, equipment, technologies and personnel.

At AgraForm, we provide the facilities, expert manufacturing specialists and deep expertise to formulate quality chemical products. With our central location in St. Louis, Missouri, we also provide extensive on-site storage and direct access to air, road, and rail transportation to support just-in-time supply chains and delivery.

Contact Us to Get Started Today

How Much Does Bulk Formulation Cost?

The cost of formulation services varies depending on the product manufactured, batch requirements, process specifications and requirements for equipment and space that your formulation plant must meet. Contact AgraForm today for a complementary price quote.