Suspension Concentrates

Services for Suspension Concentrate Products

Manufacturing stable suspension concentrates is a balancing act between keeping viscosity high enough that solids remain suspended, but low enough that your concentrate will move easily through our equipment and your end-customers’ equipment. Preventing air entrainment during manufacturing and shipping is key to avoid foaming and de-mixing of active ingredients, and mixing must be done carefully to avoid heterogeneous flocculation.

The AgraForm team works with suspension concentrates everyday and our facility is optimally designed to successfully create SC formulations in bulk. From our equipment capacities to our onsite quality assurance lab, we are designed to ensure the highest quality manufacturing of your soluble active ingredient flowables. Specific services we offer include:

- Lab Formulation

- Bulk Formulation

- Particle Sizing & Milling Services

- Spray Drying Services

- Packaging - Supersacks, Drums and Small Bags

- Tank Farm Services

- Foreign Product Certification

Request a Quote

“*” indicates required fields

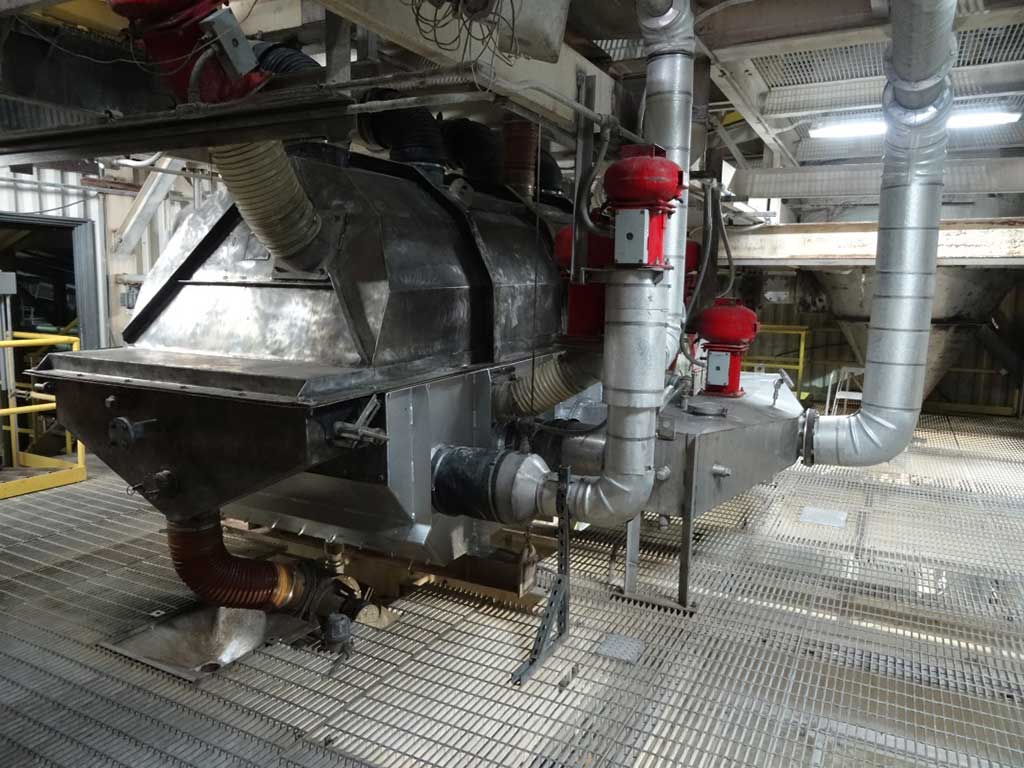

Suspension Concentrate Mixing Areas

FAQ's for SC Formulations

What are suspension concentrates?

Suspension concentrate (SC) formulations are liquid products such as fertilizers, pesticides and other agri-chemicals that have active ingredients (small solids) dispersed in water. They are more effective than emulsified concentrate (EC) and wettable powder (WP) formulations due to the fact that a stable SC must have active ingredients that remain insoluble under all temperature conditions. They are most commonly made by taking a solid active ingredient that does not dissolve in water or oil and impregnating onto, or combining it with, a substance such as clay. This is often done in a spray dryer. The solid mixture is then ground to a fine powder through milling and suspended in a small amount of liquid, usually water through a mixing process. Common ingredients include wetting agents, dispersants, viscosity modifiers (thickeners) and preservatives.

Products that work well as suspension concentrates are adjuvants, dispersants, rheology modifiers, wetting agents and co-dispersants; products such as pesticides, fungicides, insecticides, biocides, etc.

What are the benefits and drawbacks to SC formulations?

The benefits of SC formulations include dust elimination; non-flammable; suitable for most active ingredients with low water solubility; ease of use and adjuvants can be easily added in for bio enhancement. They are more effective than Emulsified Concentrate (EC) and Wettable Powder (WP) formulations.

Drawbacks include: You can’t use them with water soluble active ingredients; they require moderate agitation to stay suspended; crystals can form if partially soluble ingredients are above 0.2% of solubility in the solvent; internal wear of equipment can be caused by the suspended solids; careful handling and thorough agitation is required to prevent spills and ensure flowables haven’t settled; and stability can be hard to maintain over the long-term and upon dilution.

Is there a difference between a suspension concentrate and a soluble concentrate?

Suspension concentrate (SC) and soluble concentrate are used inter-changeably and are both usually referring to water-soluble suspended concentrate (SC) formulations where solid active ingredients are suspended in water or another solvent.

There are other types of liquid concentrates, such as:

- Emulsified concentrates (EC) which are similar to suspended concentrates except that active ingredients are suspended in an oil base and then use a surfactant to emulsify the solid/oil mix into water. EC concentrates form an oil-in-water emulsion upon dilution.

- Microemulsifiable concentrate (MEC)/Microemulsion concentrate (MC)’s are essentially the same thing as emulsified concentrates, but form a microemulsion upon dilution in water. MC’s generally have a lower concentration of active ingredients than MEC’s and MEC’s tend to contain more surfactants than other formulation types.

- Suspoemulsions (SE) are water-based like suspension concentrates, but contain both suspended solids and emulsion droplets. These are the hardest to design and require prevention of both solid settling and emulsion creaming.

- Soluble liquids (SL) contain a dissolved active ingredient usually dissolved into water. They mix easily with water and do not usually require much agitation.

There are other dry flowables such as wettable powders, water dispersible granules and spreadable granules that you can explore on our dry flowables page.

What do suspend SC mixing and packaging services cost?

Our facility is optimized for SC concentrate formulation and we help you save money throughout the process by offering efficient access to raw materials, manufacturing systems and distribution. Costs for individual products are based on several factors including:

- What raw materials are required to manufacture your product? Raw material costs can vary, but we have many common process formula inputs onsite in bulk that offer you a cost advantage at AgraForm.

- What processing steps are involved? Some products require more complicated mixing, drying and processing steps, which adds costs.

- How much product are you planning to contract out? As a bulk biocontrol manufacturer, we can offer discounts to larger batches of product outputs, but also offer an affordable test facility for smaller product runs.

- Which tests must be performed to ensure quality standards are being met? More tests, and certain types of tests, increase expense but are necessary to ensure quality. Our experienced process experts make sure your products are up to spec without costing you more by over-testing.

There are other varying factors, but those are the largest ones. For an exact cost estimate, please contact us or call 314-353-5325.

How do I get started?

If you have a lab formulation and want to start scaling up to full manufacturing, or you are looking for additional production capacity, now is the time to reach out to AgraForm. Simply Call (314) 353-5325 or fill out our contact form and one of our process experts will get in touch with you by the next business day.

We offer suspension concentrate (SC) manufacturers turnkey bulk formulation and scale-up services including product formulation, mixing, spray drying, packaging and shipment.