Dry Flowables

Services for Dry Flowable Products

The key to quality in most Dry Flowables is correct particle sizing and dust reduction. Correct, uniform particle sizing will ensure flowability for end users and the correct concentration of active ingredients.

The team at AgraForm has decades of experience manufacturing Dry Flowables in bulk. From lawn care products to commercial fertilizers, our milling, spray drying and dry packaging lines are optimized to ensure correct handling of Dry Flowables throughout the making process. Our onsite quality lab ensures proper formulation and sizing, and our immaculate safety record means you don’t have to worry about inadvertent dust exposure. Specific services we offer for Dry Flowables include:

- Lab Formulation

- Bulk Formulation

- Particle Sizing & Milling Services

- Spray Drying Services

- Packaging - Supersacks, Drums and Small Bags

- Tank Farm Services

- Foreign Product Certification

Request a Quote

“*” indicates required fields

Dry Packaging Area

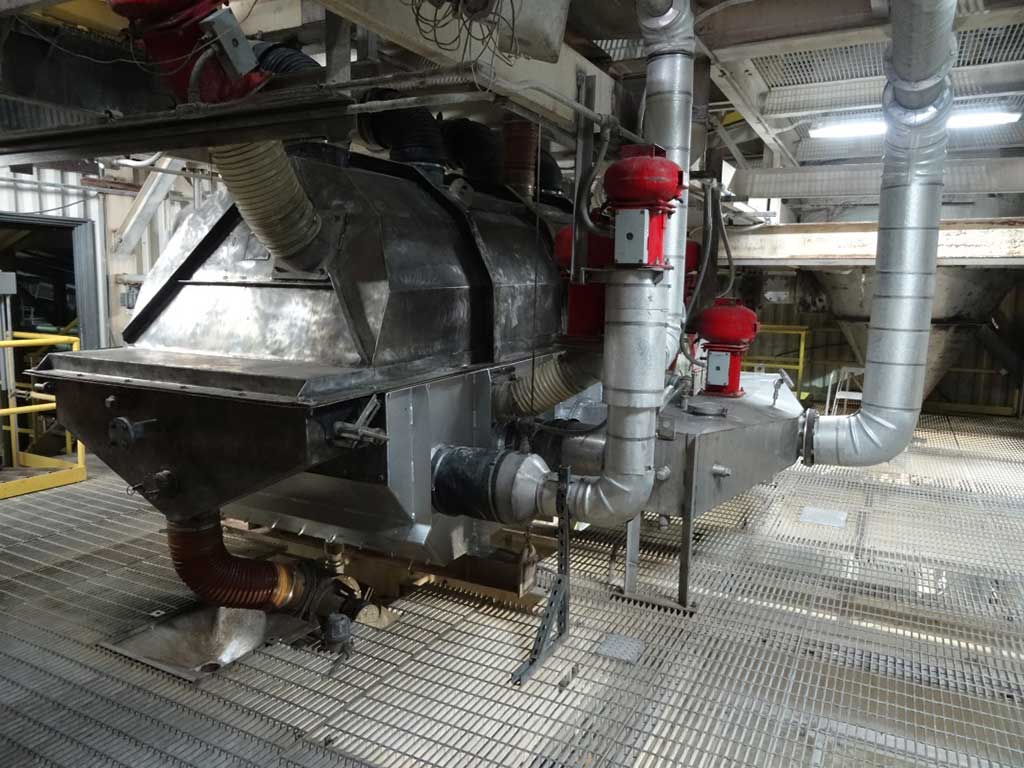

Milling Equipment

Dry Flowables FAQ's

What Dry Flowables Do You Contract Manufacture?

We work with all dry flowables common to the agri-chemical arena. The most common types of dry flowables we work with include:

- Water Dispersible Granules (WG or WDG) – are similar to wettable powders, except the particle size is larger and the overall product is less dust prone. They form a suspension when dispersed in water and require agitation to prevent settling. Check out our information on this page.

- Granules (GR) – are dry flowables made up of carrier particles that contain active ingredients and are designed to be spread over a surface. They should be dust minimal and easily break apart upon contact with water.

Are You an SC Formulation Plant?

Yes, we work extensively with suspended concentrate (SC) formulations. You can see our complete list of SC formulation services on this page

We can grind or mill your dry flowables to the correct particle size for processing into suspended concentrates. We have several milling areas, including a milling pilot scale system that can achieve nearly any particle size required for SC formulation. Please contact us or call 314-353-5325 for more information on this.

What does it cost to formulate and package dry flowables?

Cost is mainly determined by several factors:

- What raw materials are required to manufacture your product? Raw material costs can vary, but we have many common process formula inputs onsite in bulk that offer you a cost advantage at AgraForm.

- What processing steps are involved? Some products require more thorough milling or additional processing steps which can add costs.

- How much product are you planning to contract out? As a bulk dry flowables manufacturer we can offer discounts to larger batches of product outputs, but also offer an affordable test facility for smaller product runs.

- Which tests much be performed to ensure quality standards are being met? More tests, and certain types of tests, increase expense but are necessary to ensure quality. Our experienced process experts make sure your products are up to spec without costing you more by over-testing.

There are other varying factors, but those are the largest ones. For an exact cost estimate, please contact us or call 314-353-5325

How do I get started?

If you have a lab formulation and want to start scaling up to full manufacturing or you are looking for additional production capacity, now is the time to reach out to AgraForm. Simply Call (314) 353-5325 or fill out our contact form and one of our process experts will get in-touch with you by the next business day.

We offer agri-chem manufacturers turnkey bulk formulation and scale-up services for dry flowables including product formulation, milling & grinding, spray drying, packaging and shipment.