Spray Drying Process

The spray drying process is a way to produce a dry powder from a slurry or liquid by rapidly drying it. It’s a preferred manufacturing method as it allows for very consistent and fine particle sizes and works well with heat-sensitive materials. Air and nitrogen are typically used during the drying process, depending on the materials in production.

Serving chemical producers nationwide from our state-of-the-art facilities in St. Louis, Missouri; AgraForm is one of the most trusted contract spray drying companies in America.

Our Spray Drying Process, Equipment & Capabilities

With an average daily production rate of more than 30,000 pounds, our industrial spray drying plant facility offers the capacity, efficiency and equipment to get the job done no matter how big.

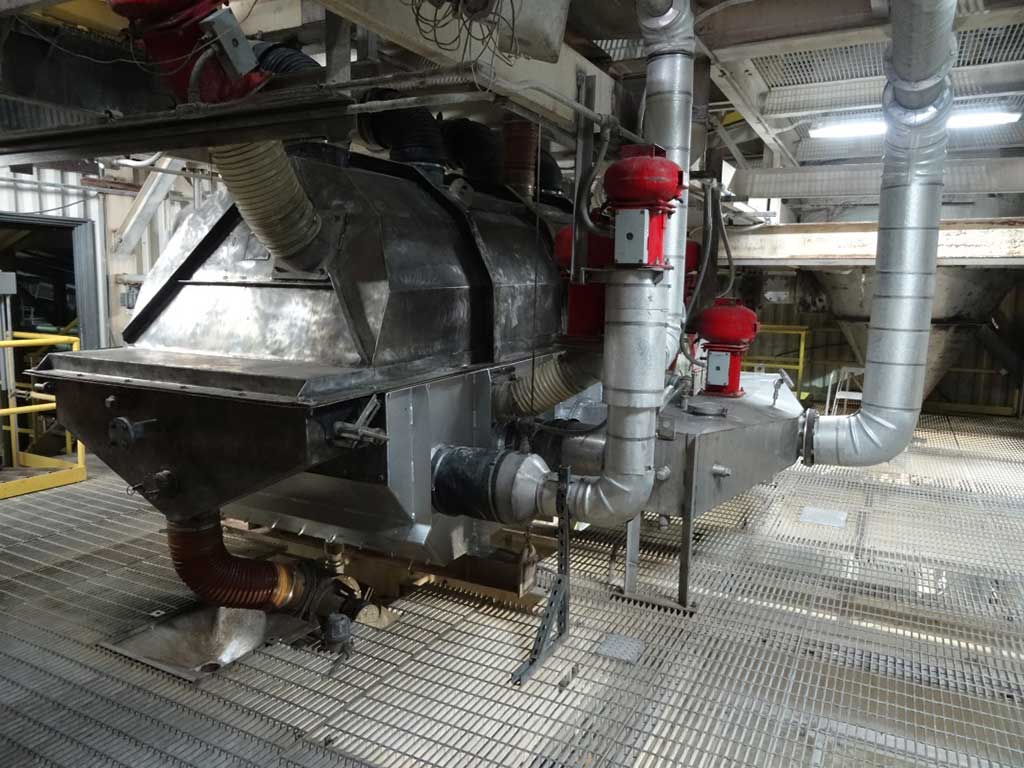

Spray Drying Plant

- Our Spray Dryer is a 60 ft. gas-fired co-current atomization tower

- It’s combined with a secondary fluid bed dryer for additional drying/cooling

- Average daily production rate: 30k LBS/Day

Dry Granule Packaging Options

- Super Sacks

- Drums

- Bottles

- Vertical Form Fill Seal (VFFS) Bags

Bulk Storage Capacity

We also have a 60,000 pound bulk storage capacity available in our secondary packaging bin.

Contact Us About Contract Spray Drying Services

Contract spray drying services is just one of the complete, end-to-end manufacturing services we provide. Whether you simply need a contract spray drying company or a more robust manufacturing partner, we can help. With a decade in business, state-of-the-art equipment and rigorous process control, we’ll get the job done. Day in and day out.

Request a Quote

“*” indicates required fields

Our Spray Drying Tower